Regular fire extinguisher inspections are a non-negotiable part of keeping your site safe and compliant, especially in Australian manufacturing and construction. This is not just about ticking boxes for regulators; it’s about making sure your gear will work when you need it most.

This guide gives you practical steps for keeping your fire extinguishers ready and your site compliant.

Why Fire Extinguisher Inspections Matter

Let's get straight to it. A fire can double in size every 60 seconds. In that critical moment, a faulty or inaccessible extinguisher is useless. On a busy construction site or factory floor, these simple checks are your first line of defence against a small problem becoming a disaster.

Ignoring this stuff has real consequences. Non-compliance can lead to big fines and stop-work orders, disrupting projects and hitting your bottom line. More importantly, it puts everyone on your site at risk. If a small, controllable fire gets out of hand because an extinguisher failed, the operational and personal costs can be huge.

Who Is Responsible on Your Site?

Responsibility for inspections is usually layered. A certified technician will handle the detailed annual servicing, but the day-to-day accountability for routine checks falls to your people on the ground.

This typically includes:

- Health and Safety Managers who organise the overall inspection program.

- Site Supervisors or Foremen who are often in charge of overseeing the monthly visual checks.

- Designated team members who are trained to perform the quick, hands-on inspections.

Ultimately, everyone has a role to play in making sure equipment is accessible and appears ready for use.

Understanding Australian Standards

The key standard you need to know in Australia is AS 1851. This document outlines the routines for servicing and maintaining fire protection systems and equipment. It details everything from the monthly visual checks right through to five-yearly hydrostatic pressure testing.

The fire protection services industry in Australia is a big deal, and regulations are tightening. For instance, upcoming changes in New South Wales, effective from 13 February 2026, will mandate strict adherence to AS 1851-2012 for servicing essential fire safety measures. You can learn more about the fire protection services industry findings on ibisworld.com.

A working knowledge of AS 1851 is essential for any Health and Safety Manager. It provides the clear, practical framework for building a compliant and effective inspection program on your site, which is exactly what the rest of this guide will help you do.

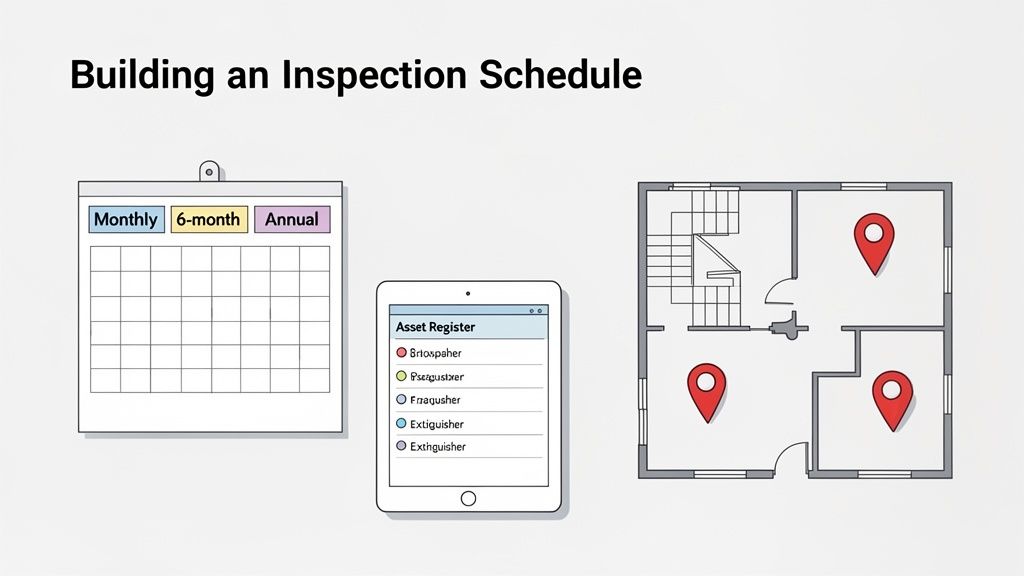

Building Your Inspection Schedule

A proper inspection starts long before you touch an extinguisher. It begins with a clear, organised schedule that makes sure nothing gets missed. On a busy industrial site, just winging it is a recipe for non-compliance and big gaps in your fire readiness.

Putting a solid schedule together means mapping out all your assets and understanding the different check frequencies required by Australian Standards. Think of it as your blueprint for repeatable and effective fire extinguisher inspections. This process turns a huge, overwhelming job into a set of manageable, recurring tasks.

Mapping Your Extinguisher Locations

First things first: you need to know exactly what you have and where it all is. Walk the entire site with a floor plan, or even better, a tablet, and mark the precise location of every fire extinguisher. This map becomes an essential tool for both your own team and any external service technicians.

On a large construction site, it is very easy for an extinguisher in a quiet storage area or behind a rarely used machine to be forgotten. A physical map stops this from happening. It also helps you spot potential issues, like areas with poor coverage or extinguishers placed in high-risk zones where they could be damaged by forklifts or other machinery.

Once the map is done, the next move is building a simple asset register.

This does not need to be a complicated document. It just needs to track:

- Unique ID Number: Give each extinguisher a simple code (e.g., WH-01 for Warehouse 1, MN-01 for Maintenance Bay 1).

- Location: Describe its exact spot based on your map.

- Type: Note the type (e.g., ABE Dry Powder, CO2, Water, Foam).

- Size: Record its size (e.g., 9.0kg, 2.5kg).

- Last Service Date: This is critical for keeping track of your annual and five-yearly requirements.

A basic spreadsheet or a digital tool gets the job done and gives you a single source of truth for your entire extinguisher inventory.

Understanding Inspection Frequencies

Australian Standards lay out clear minimum frequencies for different types of checks. Getting these mixed up is a common mistake that can easily lead to compliance headaches.

The Australian fire extinguisher market is growing, partly because standards like AS 1851 demand consistent checks. This has created a robust industry focused on keeping equipment ready, reflecting how seriously businesses are now taking fire safety not just for compliance but to protect their operations. To see the full scope of this market, you can find more details in the Australian fire extinguisher market analysis on expertmarketresearch.com.au.

Here’s a quick-reference table that breaks down the inspection frequencies you need to follow under the Australian Standards.

Australian Fire Extinguisher Inspection Frequencies

| Inspection Type | Frequency | Who Typically Performs It | Key Focus Areas |

|---|---|---|---|

| Visual Inspection | Monthly | Site Safety Officer, Team Leads, or trained staff | Check for accessibility, pressure gauge in the green, intact pin/seal, and obvious physical damage. |

| Detailed Service | Six-Monthly | Certified Fire Technician | A more thorough check of all components, including weighing the extinguisher and updating the service tag. |

| Annual Service | Annually | Certified Fire Technician | Includes all six-monthly checks plus a detailed inspection of the extinguisher's condition and mechanics. |

| Pressure Testing | Every 5 Years | Certified Fire Technician | A hydrostatic test to check the cylinder's integrity. The manufacture date is stamped on the cylinder. |

Sticking to this schedule is non-negotiable for meeting your obligations under AS 1851.

Getting the Right Tools Ready

To make your monthly visual inspections quick and effective, your team needs the right gear. This does not have to be complicated. A simple kit with a clipboard holding your asset register and checklist, a pen, and some spare zip ties for replacing broken tamper seals (if your procedures allow) can work.

A much better approach, though, is to use a tablet with a digital checklist. This lets you snap photos of any faults, automatically time-stamps the inspection, and stores the record digitally. Instantly, you have a perfect, unshakeable audit trail.

To help with these ongoing checks, check out the best recurring task app options to help automate the routine. When you set up simple systems like this, you make it easy for your team to perform consistent, high-quality inspections every single time.

Your Monthly Visual Inspection Checklist

Alright, let’s get down to the practical side of things. This is where you roll up your sleeves and get hands-on.

The monthly visual inspection is your first line of defence in fire safety, and it’s one of the most crucial parts of your whole routine. It’s a quick check that anyone on your team can be trained to do, and it's designed to catch the most common problems before they become bigger risks.

Think of it as a rapid health check for your extinguishers. In a busy workshop or on a fast-moving construction site, a lot can happen in 30 days. A forklift might knock an extinguisher off its bracket, someone might use it for a minor flare-up and not report it, or it could just slowly lose pressure. This checklist is how you spot those issues, fast.

Is the Extinguisher Easy to See and Reach?

The best fire extinguisher in the world is useless if no one can find it or get to it when things go sideways. This is the absolute first thing you check.

When you walk up to where the extinguisher should be, ask yourself:

- Is it visible? Can you see the signage clearly? On a construction site, has a stack of plasterboard or a new pallet of materials been dumped in front of it?

- Is there a clear path? Can someone grab it in a hurry without tripping over tools, machinery, or boxes? You need to maintain a clear access zone of at least one metre around it.

- Is it mounted correctly? The extinguisher needs to be on its proper bracket. If it's sitting on the floor, it can be damaged, kicked over, or, and I’ve seen this more times than I can count, used as a doorstop.

An extinguisher blocked by a tool cart in a workshop is a classic, everyday failure. It’s a simple fix, but one that could make all the difference when every second counts.

Checking the Pressure Gauge

The pressure gauge is the extinguisher's pulse. It tells you instantly if the unit has enough pressure to discharge its contents effectively.

Take a look at the small dial, usually found right at the top near the handle. The needle absolutely must be pointing within the green zone.

If the needle is in the red, it’s an immediate fail. A needle in the lower red section means it's undercharged and won't have the power to spray properly. If it’s in the upper red section, it's overcharged, which can be just as dangerous and points to a serious fault.

An undercharged extinguisher is probably the most common fault found during these monthly checks. It’s usually caused by a slow, unnoticed leak.

Inspecting the Pin and Tamper Seal

The safety pin and tamper seal are simple but critical. The safety pin is the metal ring that stops the handle from being squeezed by accident. The tamper seal is just a thin plastic tag that breaks the moment the pin is pulled.

Your check here is simple:

- Is the pin in place? It should be fitted securely through both sides of the handle.

- Is the tamper seal intact? A broken or missing seal is a massive red flag. It means the extinguisher might have been used, tampered with, or the pin was pulled and then shoved back in.

On a construction site, for instance, it’s not unheard of for someone to pull the pin out of curiosity or to shift an extinguisher, then pop it back in without replacing the seal. Without that intact seal, you have no guarantee the unit is fully charged and ready. It has to be tagged out of service and sent for professional servicing immediately. To see how these specifics fit into a bigger picture, it's worth reviewing a comprehensive workplace inspections checklist to understand the full scope of a good safety assessment.

Examining the Physical Condition

Now it’s time to give the extinguisher itself a proper once-over. You’re looking for any physical damage that could compromise its integrity, especially under pressure.

Run your eyes and hands over the whole unit. You're looking for:

- Dents, scratches, or gouges: Big dents on the cylinder are a serious problem. They can weaken the canister and create a rupture risk.

- Corrosion or rust: Pay close attention to the base and any welded seams. In humid environments or outdoor areas, rust can take hold fast and eat through the metal.

- Leaking or residue: Check for any powder or liquid around the nozzle or handle, a dead giveaway of a leak.

A classic real-world example is an extinguisher located near a chemical storage area. Fumes and vapours can cause accelerated corrosion, which is exactly the kind of thing a quick monthly check is designed to catch early.

Hose and Nozzle Inspection

Finally, check the delivery system. If the hose or nozzle is blocked or damaged, the extinguishing agent is not going anywhere.

Gently flex the hose and inspect it for:

- Cracks, splits, or tears: The hose should be flexible and free from damage. Rubber and plastic can get brittle over time, especially with exposure to sunlight or extreme temperatures.

- Blockages in the nozzle: Peer into the nozzle opening to make sure it's clear. It’s a prime spot for insects, dirt, or debris to build a home, particularly on dusty sites. A small wasp nest or a clump of mud can completely block the discharge.

During an inspection at a welding bay, you might find tiny bits of hot slag have melted onto the nozzle. That creates a dangerous blockage that only a hands-on visual check like this would find.

Once you've run through these steps, you'll have a clear picture of whether that extinguisher is ready for action. If it passes every check, sign off the inspection tag and move on. If it fails on any point, it's time to take it out of service and get it sorted.

How to Handle a Failed Inspection

Finding a faulty extinguisher during your monthly visual inspection is not a failure; it's a win for your system. It means your checks are working exactly as they should. But what you do next is what keeps your site compliant and protected. A failed inspection calls for immediate, methodical action, not just a note on a clipboard.

The absolute first step is to take the faulty unit out of service straight away. It cannot be left in its designated spot where someone might grab it in an emergency, assuming it works. This is all about preventing a bad situation from becoming worse.

Immediate Actions: Tag and Remove

The moment an extinguisher fails any part of your inspection, it needs to be clearly marked as unusable. Grab a dedicated 'Out of Service' tag and fix it to the unit. This tag should be durable and highly visible, leaving no room for doubt about the extinguisher's status.

Once it's tagged, physically remove the extinguisher from its mounting bracket. Do not just leave it sitting on the floor nearby where it could still be mistaken for a working unit. Move it to a designated, secure area for faulty equipment, like a maintenance workshop or a specific storage cage. This stops any accidental use and keeps it safe until it can be properly assessed for repair or replacement.

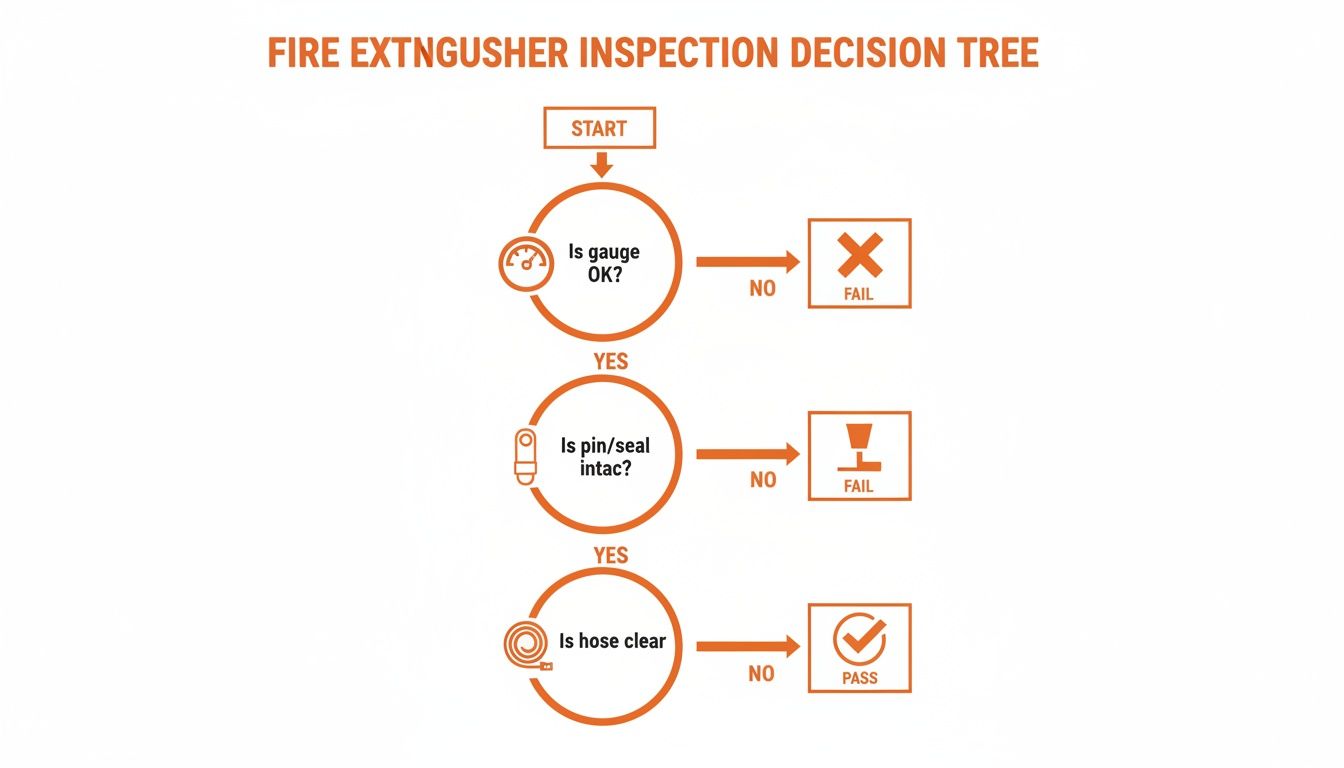

This decision tree infographic gives you a quick visual guide to the pass or fail points of an inspection.

As the visual makes clear, a 'no' at any stage of the check, from the pressure gauge to the hose condition, results in an immediate failure, requiring prompt action.

Finding a Temporary Replacement

Removing a faulty extinguisher creates a gap in your fire coverage. According to Australian standards, you must maintain the required level of protection at all times. This means you need to find a temporary replacement immediately, not tomorrow.

Your options for a replacement are straightforward:

- Use a spare unit: It’s good practice to keep a small number of serviced, ready-to-use spare extinguishers on-site for exactly this kind of situation.

- Relocate from a lower-risk area: In some cases, you might be able to temporarily move a compliant extinguisher from a nearby, lower-risk location to cover the gap. Just be sure to document this move in your records.

The key is to act fast. Leaving an area unprotected, even for a short time, is a significant compliance and safety risk you do not want to take.

When to Escalate the Issue

Once you've made the immediate area safe, you need to decide the next step for the faulty unit. The problem itself often dictates the solution. Some issues require professional help, while others might have simpler fixes your team can handle.

This decision-making process is critical. You must determine if the fault is something your team can address or if it's time to call in the professionals.

A common scenario in a manufacturing plant is finding an extinguisher with a pressure gauge sitting in the red. This is an automatic failure that cannot be fixed on-site. It requires a certified fire service technician to inspect, test, and correctly recharge the unit.

Here’s how to triage some common problems:

- Simple Fixes (On-Site Team): Issues like a blocked nozzle (if it can be safely cleared), a broken mounting bracket, or obscured signage are typically things your maintenance team can sort out.

- Professional Service Required (Certified Technician): Any problem related to pressure, the integrity of the cylinder, or internal mechanics is a job for the experts. This includes a low or high-pressure reading, a broken tamper seal (which implies potential use), significant dents or corrosion, or if the unit is due for its six-monthly or annual service.

Properly documenting these faults is crucial. When you find a problem, you should detail what went wrong and the actions you took. Using a non-conformance reporting process creates a clear, auditable trail. For a deeper look into this process, you can learn more about how to manage a non-conformance report effectively.

Never attempt to repair pressure-related issues yourself. Fire extinguishers are pressurised vessels and can be dangerous if handled incorrectly. Always call in a certified technician for anything beyond the most basic external fixes.

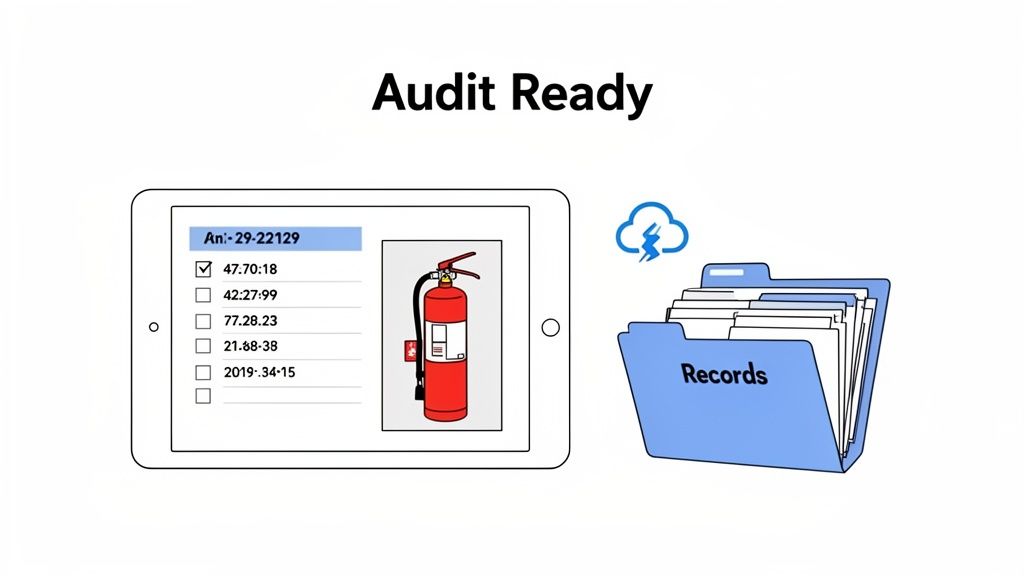

Keeping Records That Are Audit Ready

Once you’ve dealt with any faults from a fire extinguisher inspection, the final piece is documenting everything. It’s a simple rule of thumb in safety: if you did not write it down, it did not happen, at least not in the eyes of an auditor or during an incident investigation. Keeping clear, accurate, and easily accessible records is not just good practice; it's required for compliance.

Those messy paper logbooks in a dusty filing cabinet or confusing spreadsheets on a shared drive are relics of the past. They’re a nightmare to track, easy to lose, and almost impossible to analyse for recurring problems. Shifting to a digital system is the only practical way to build a solid, dependable evidence trail for your fire extinguisher inspections.

This is what a modern approach looks like. A platform like Safety Space centralises all your inspection records, making them instantly available whenever you need them.

Ditching Paper for Digital Efficiency

The real game-changer with a digital platform is automation. Forget manually tracking dates on a wall calendar. You can schedule all your recurring inspections (monthly, six-monthly, and annual) and assign them directly to the right people. The system then sends out automatic reminders, meaning checks are far less likely to be missed.

When it's time for an inspection, your team member just grabs a tablet, opens the task, and works through a pre-built digital checklist. This guarantees every single check is performed consistently, every single time. No more guesswork or forgotten steps.

The real power comes from the data you can capture on the spot. If an inspector finds a pressure gauge in the red, they can snap a photo with the tablet and attach it directly to that inspection record. Suddenly, you have undeniable, time-stamped evidence of the fault.

This kind of instant record-keeping is what makes your documentation truly audit-ready. An auditor can see exactly when the check was done, who did it, what they looked at, and the photographic proof of any issues. It cuts administrative time and puts you in a much stronger compliance position. To see how this fits into a bigger picture, you can learn more about building a complete document management program and how it shores up your entire safety framework.

What Makes a Record Audit Proof?

An audit-proof record is one that tells a complete and verifiable story. It needs to contain specific details that leave no room for questions or doubt.

Your digital inspection records should always capture:

- Asset Identifier: The unique ID of the fire extinguisher (e.g., WH-01).

- Location: Where exactly the unit is located on your site map.

- Inspector's Name: The person who performed the check.

- Date and Time Stamp: An automatic, unchangeable record of when the inspection happened.

- Checklist Results: A clear pass or fail for each item on the list.

- Notes and Photos: Any comments on the unit’s condition and photographic evidence of any faults.

- Corrective Actions: A log of the steps taken to fix failures, who was assigned the task, and when it was completed.

This level of detail creates a closed-loop system. You can prove not only that you found a problem but that you took immediate and appropriate action to fix it. This is exactly what safety regulators want to see.

Preparing for a Compliance Audit

When an auditor shows up, the last thing you want is a frantic scramble for paper records. With a digital system, you can pull up all the required documentation in seconds. You can filter by date range, location, or asset type to give them the exact information they’ve asked for, right there and then.

This organised approach shows a professional and serious commitment to safety. It proves your inspection program is a living process, not just a box-ticking exercise done once a year. If you want to be certain your records tick all the boxes, exploring some compliance audit templates can be a massive help.

Ultimately, strong record-keeping is not just about passing audits. It’s about having the data you need to spot trends. Are extinguishers in a specific workshop failing more often? It might point to an underlying environmental issue, like high humidity causing corrosion, that needs a bigger fix. This is how you move from just reacting to problems to proactively making your workplace safer.

Fire Extinguisher Inspection FAQs

Even with a rock-solid inspection plan, questions are going to pop up. Getting straight, practical answers is what keeps your program ticking and your site compliant. Here are a few of the most common queries we get from Health and Safety Managers.

How Long Do Fire Extinguishers Last In Australia?

While the cylinder itself is built tough, the real expiry date you need to watch is for the pressure test. Under Australian Standard AS 1851, every fire extinguisher must undergo a hydrostatic pressure test every five years. This clock starts from the date of manufacture, which you'll find stamped right on the cylinder.

Your regular visual checks are an early warning system. They’re your best bet for spotting issues long before that five-year deadline. If an extinguisher ever fails a pressure test or shows serious corrosion or damage, it's immediately retired from service. No second chances.

A hydrostatic test is not just a quick look-over. It's a specialised process done by certified pros to check the cylinder's structural integrity, making sure it can safely hold its charge without any risk of rupture.

That five-year rule is a hard stop. Without that re-certification, the extinguisher is out.

Can I Perform All Fire Extinguisher Inspections Myself?

Yes and no. You and your team on-site are absolutely expected to handle the routine monthly visual inspections. These checks are designed to be done quickly by any competent person who knows what to look for, just like we've outlined in our checklist.

But the more technical work has to be left to the professionals.

- Six-monthly and annual servicing requires a qualified and certified fire technician.

- Five-yearly pressure testing and recharging also demand specialised gear and training.

These technicians have the specific tools and know-how to properly test the extinguisher's guts and guarantee it will work as intended when you pull the pin.

What Is The Most Common Reason An Extinguisher Fails Inspection?

From what we see every day on industrial and construction sites, the two biggest culprits for a failed visual check are incorrect pressure and physical damage. A pressure gauge with the needle sitting in the red, either too low from a slow leak or too high from a fault, is an instant fail.

Other frequent problems you'll spot in a monthly check include:

- A missing or broken tamper seal, which is a dead giveaway that the extinguisher might have been used or messed with.

- A nozzle blocked with dirt or debris. This is a huge issue on dusty construction sites.

- Dents and corrosion on the cylinder itself, usually from a knock by a forklift or just from being in a humid or corrosive factory environment.

These simple issues are exactly why consistent monthly fire extinguisher inspections are so critical. They let you catch the small problems before they have a chance to become big, life-threatening risks.

Ready to stop chasing paperwork and build an audit-proof safety system? Safety Space replaces messy spreadsheets and paper forms with a simple, all-in-one platform. Schedule inspections, complete digital checklists on-site, and store every record automatically for instant, audit-ready evidence. Book your free demo and H&S consultation at safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.