A workplace safety and health policy is your company's formal commitment to keeping people safe. It's the operational backbone of your safety system, spelling out exactly how you plan to manage risks and meet your legal duties under Australia's Work Health and Safety (WHS) laws.

Your WHS Policy Is More Than Just a Document

Let's be clear: a policy on safety and health isn't just about ticking a compliance box. When done right, it's a practical tool that actively prevents incidents and shields your business from serious legal and financial trouble.

For high-risk industries like construction and manufacturing, it’s not optional; it’s absolutely essential. A well-written policy stops being a piece of paper in a folder and becomes a daily guide for your team.

This document sets the foundation for all your safety procedures. It clearly states your company's commitment and sets expectations for everyone, from senior management down to the newest hire and every subcontractor on site. Without this formal statement, safety efforts can become inconsistent, leaving dangerous gaps in your operations.

Understanding the Legal and Practical Stakes

The legal requirements under Australia's harmonised Work Health and Safety (WHS) Act are strict. A documented policy is a key part of proving you are meeting your primary duty of care as a Person Conducting a Business or Undertaking (PCBU). Failing to establish and implement one can lead to significant fines and legal action, especially if an incident occurs.

The statistics really drive home why this is so critical. In a recent year, Australia recorded 188 work-related fatalities. High-risk industries like construction, manufacturing, and transport accounted for a staggering 80% of traumatic fatalities and 61% of serious compensation claims. These aren't just numbers; they represent the real-world impact of workplace hazards and highlight the absolute need for a robust policy to manage known risks like vehicle incidents and falls from height. You can find out more by reviewing these key WHS statistics for Australia.

Turning Policy into Practice

A good WHS policy does much more than just satisfy regulators. It provides a clear framework that helps your team make safe decisions, day in and day out. It needs to cover key areas such as:

- Hazard Identification: How you will spot potential dangers before they can cause harm.

- Risk Control: The specific steps you will take to eliminate or minimise those risks.

- Emergency Procedures: What to do when something goes wrong, from first aid to a full site evacuation.

- Consultation: How you will actively involve your workers in safety matters.

To help you get started, here's a quick overview of the non-negotiable elements every safety and health policy must contain.

Core Components of a WHS Policy

| Component | What It Covers | Why It's Important |

|---|---|---|

| Commitment Statement | A clear declaration from leadership committing to a safe and healthy workplace. | Sets the tone from the top and shows that safety is a core business value. |

| Objectives & Targets | Specific, measurable safety goals (e.g., reduce LTI by 10% this year). | Provides clear direction and a way to measure the success of your safety program. |

| Responsibilities | Defines who is responsible for what, from the CEO to frontline workers. | Eliminates confusion and ensures accountability at all levels of the organisation. |

| Consultation Process | Outlines how workers will be consulted on safety matters that affect them. | Meets legal requirements and leverages the knowledge of those doing the work. |

| Hazard & Risk Management | The process for identifying, assessing, and controlling hazards. | This is the core engine of your safety system, designed to prevent incidents. |

| Emergency Procedures | Details the response plan for incidents, accidents, and emergencies. | Ensures a coordinated and effective response when things go wrong. |

| Training & Induction | How you will ensure all workers have the necessary safety training and information. | Equips your team with the knowledge to work safely and handle risks. |

| Policy Review | The schedule and process for regularly reviewing and updating the policy. | Keeps your policy relevant, effective, and compliant with changing laws. |

Having these components in place creates a solid foundation, ensuring your policy is complete and genuinely useful.

The real value of a safety and health policy is its ability to create clarity and consistency. When everyone knows their responsibilities and follows the same set of rules, you reduce the chances of misunderstandings that can lead to accidents.

To ensure your policy is truly effective, it helps to see how it fits within the bigger picture of effective workplace policies. This helps position your safety policy within a larger operational framework, making it a more integrated and functional part of your business.

Building Your Policy From the Ground Up

Drafting a WHS policy can feel like a mountain to climb, but it doesn't have to be stuffed with legal jargon. Forget the generic templates that just end up collecting dust on a shelf. Your goal is to create a practical, living document that actually guides what your crew does every day on the factory floor or construction site.

That means tailoring every single clause to the real-world risks your team faces. Let’s break down the essential building blocks of a policy that works.

The Statement of Intent

Start with a clear, direct statement of intent right at the top. This isn't just corporate fluff; it's a public promise from the top brass that sets the tone for the entire company. It absolutely needs to be signed and dated by the most senior person in the business like the CEO or Managing Director.

This statement is your company's formal acceptance of its duty to keep everyone safe and healthy. Keep it simple enough for anyone to understand.

A real-world example:

"[Your Company Name] is committed to preventing injury and illness for all our workers, contractors, and visitors. We will provide the resources, training, and supervision needed to manage all workplace health and safety risks. Our goal is zero harm, and we expect everyone to actively participate in making that happen."

Language this direct shows that leadership is genuinely invested. It frames safety as a core business value, not just another box-ticking exercise.

Defining Key Responsibilities

A policy is useless if nobody knows who's supposed to do what. Vague phrases like "all employees are responsible for safety" don't cut it. You need to get specific and spell out exactly what's expected from different roles in your organisation.

Think about your workplace structure and assign clear, actionable tasks.

- Senior Management: Their job is to provide the resources, that means time, money, and the right gear, for safety to succeed. They also sign off on the policy and, most importantly, lead by example.

- Site Supervisors/Managers: These are the people on the ground. They're responsible for daily safety management, like running toolbox talks, making sure Safe Work Method Statements (SWMS) are actually being followed, and pulling people up on unsafe actions on the spot.

- Workers: Their responsibility is to follow the procedures, use their personal protective equipment (PPE) properly, and report any hazards or incidents to their supervisor straight away. No delays.

- Contractors: They must comply with your site's safety policy and all relevant WHS laws, on top of their own safety protocols.

By writing these roles directly into the policy, you're building accountability right into your system. There’s no more confusion about who needs to step up.

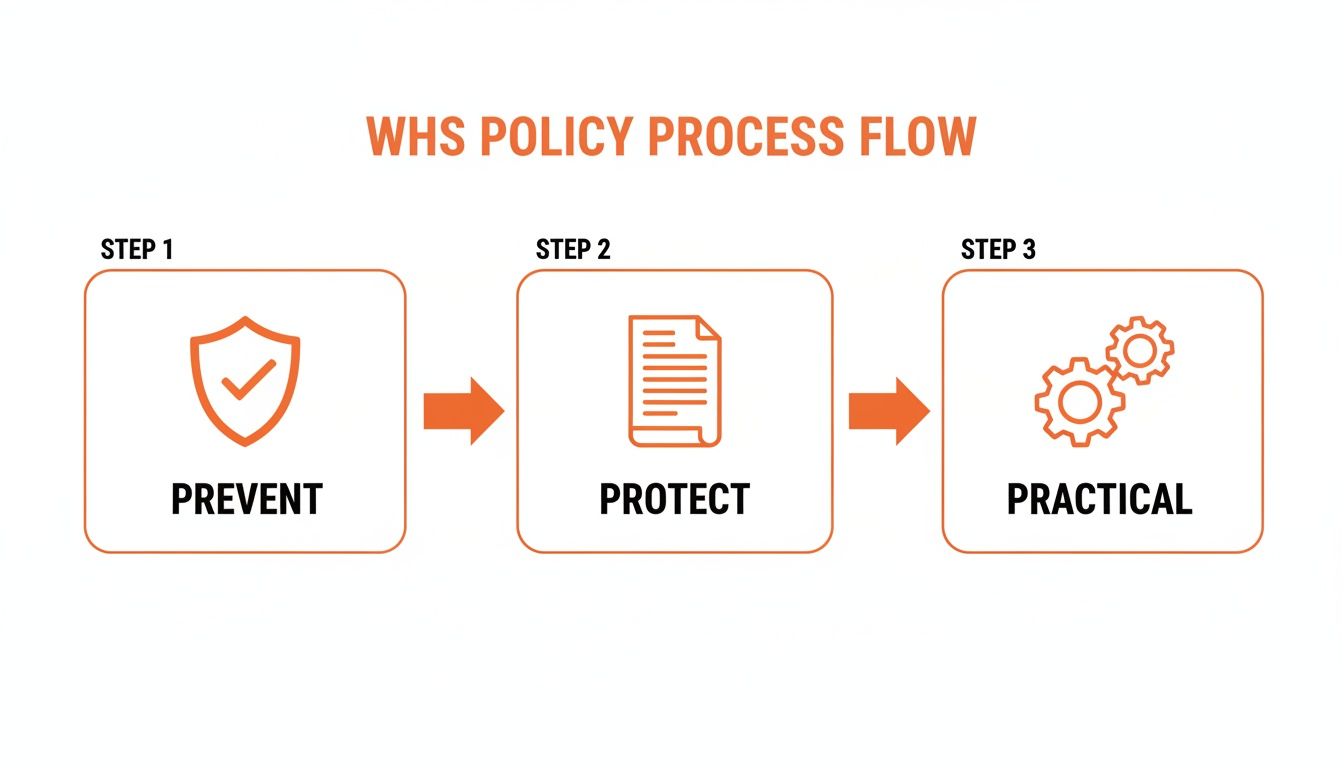

This simple process flow captures the core of a good WHS policy, moving from preventing harm to protecting people through practical, on-the-ground actions.

As the graphic shows, a great policy isn't a static document. It's an active cycle that's all about practical application to keep your workplace safe.

Outlining Core Procedures

This is the "how-to" section of your policy. It’s where you detail the specific processes your company follows to manage safety day-to-day. You don't need to cram every single procedure into the main policy document; that would make it unreadable. Instead, outline the key frameworks and then reference your more detailed documents where necessary.

Your policy must, however, clearly describe your approach to these critical areas.

Hazard Identification and Risk Assessment

Your policy needs to state how you're going to find and fix problems before they cause harm. That means having a clear process laid out.

- Identify Hazards: Explain the methods you'll use. This could be regular site inspections, talking with workers, or digging into incident investigation reports.

- Assess Risks: Briefly describe how you figure out the likelihood and severity of harm from each hazard you find.

- Control Risks: Commit to using the hierarchy of controls. This is non-negotiable. You must prioritise eliminating hazards first, then move down the list to substitution, isolation, engineering controls, administrative actions, and only as a last resort, PPE.

Emergency Procedures

The policy should confirm that you have specific, documented plans for when things go wrong. You don’t need to paste the entire evacuation map in here, but you do need to state your commitment to:

- Maintaining clear, unobstructed emergency exit paths.

- Providing proper first aid facilities and trained first aiders.

- Establishing and regularly practising procedures for events like fires, chemical spills, or medical emergencies.

For a manufacturing plant, this might mean a clause about the safe shutdown of machinery during an evacuation. On a sprawling construction site, it could detail the communication plan to reach workers who are spread out. The point is to make sure the policy directs people to the detailed plans they need in a crisis.

Assigning Clear Roles and Responsibilities

Let’s be honest: a policy fails when nobody knows who’s supposed to do what. Just saying you're "committed to safety" is nice, but it doesn't stop accidents. Your policy on safety and health at workplace needs to be a clear map, showing every single person their specific role in keeping the site safe.

Ambiguity is the enemy here. When responsibilities are vague, critical tasks fall through the cracks. This is where we move beyond generic job titles and define who is accountable for what, with absolute clarity.

This isn't just about ticking boxes; the stakes are incredibly high. Australian workplaces recently recorded 146,700 serious injury claims, with construction and manufacturing topping the list. The median time off work was 7.4 weeks per claim. Think about the operational and financial fallout from that. Clearly defined roles are the foundation for the hazard controls required by WHS law to prevent these incidents from happening in the first place.

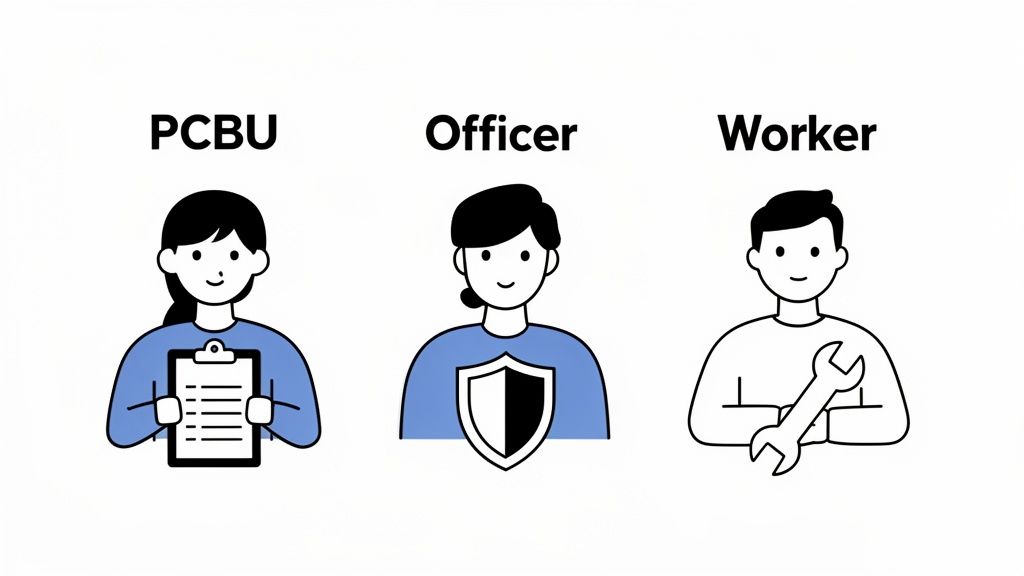

The Role of the PCBU and Officers

Under Australian WHS law, the buck stops with the Person Conducting a Business or Undertaking (PCBU). This is usually the company itself, and it holds the primary duty of care. Your policy has to state, unequivocally, that the PCBU is responsible for providing a work environment free from health and safety risks.

Officers, the senior leaders like directors and CEOs, have a personal duty of due diligence. Your policy needs to spell out exactly what that means on a practical level.

- PCBU Responsibilities: This includes providing safe machinery and structures, ensuring the safe use of substances, offering adequate facilities for workers, and delivering all the necessary information, training, and supervision.

- Officer Responsibilities: They must actively stay informed about WHS matters, understand the business’s specific hazards and risks, and ensure the PCBU has, and actually uses, the right resources to manage them.

By documenting these high-level duties, you formalise legal obligations and send a powerful message: safety leadership starts right at the top.

Detailing Manager and Supervisor Duties

This is where the policy gets its boots on the ground. Managers and supervisors are the ones who turn the company's safety promises into daily action. Their responsibilities must be specific, practical, and task-oriented.

Imagine a site supervisor on a busy residential construction project. Their duties, as defined in the policy, should be crystal clear:

- Conduct daily pre-start meetings and toolbox talks, making sure to document who attended and what was covered.

- Verify that all Safe Work Method Statements (SWMS) are in place and being followed for any high-risk construction work.

- Perform daily site inspections to spot new hazards, like unsecured scaffolding or poor housekeeping, before they cause a problem.

- Step in immediately to correct unsafe actions and report all incidents and near misses through the proper channels.

For a plant manager in a manufacturing firm, the list would be different but just as specific. It might include ensuring machinery guarding is effective, managing the lockout-tagout procedure during maintenance, and overseeing chemical handling protocols.

A policy that vaguely tells a supervisor to "ensure the site is safe" is a recipe for failure. A policy that requires them to "complete and file the daily plant inspection checklist before 9 AM" creates a clear, verifiable action.

Defining Worker and Visitor Responsibilities

Safety isn't a one-way street. Every single person on site, from the newest apprentice to a visiting client, has a part to play. Workers have a legal duty to take reasonable care of their own safety and the safety of others. Your policy must make it obvious that this is an active role, not a passive one.

Worker responsibilities should include:

- Following all lawful safety instructions and procedures without shortcuts.

- Using all provided personal protective equipment (PPE) correctly, every time.

- Reporting any hazards, injuries, or illnesses to a supervisor immediately.

- Not tampering with or misusing anything provided for health and safety.

Even visitors and subcontractors have duties. Your policy should clearly state that they must follow all site safety rules, sign in and out, and listen to the instructions of their site contact. When you make these roles explicit, you eliminate confusion and build a system where everyone knows exactly what's expected of them.

To get a deeper understanding of the functions of safety personnel, you can explore our detailed guide on the role of a Health and Safety Officer.

Making Your Policy Stick Through Consultation and Communication

Let's be honest. A perfectly written policy document gathering dust in a folder is completely useless. The single most critical step is turning that piece of paper from a management document into a team-wide commitment. How do you do that? Through genuine consultation and clear, constant communication.

Writing a policy on safety and health at the workplace in isolation is a surefire way to see it fail. Under Australian WHS law, you have a legal duty to consult your workers on things that affect their health and safety. But this isn't just about ticking a legal box; it's a practical necessity. The people operating the machinery or working at heights know the real-world risks far better than anyone sitting in an office.

Gathering Real Feedback from the Front Line

Consultation isn't sending a memo and asking for a thumbs-up. It's an active, two-way conversation. You're trying to get honest feedback from the people who will live and breathe this policy every single day.

How you do this depends on your workplace, but here are a few methods that actually work:

- Toolbox Talks: On a construction site, these quick daily meetings are gold. You can hash out a specific part of the draft policy, like a new procedure for working near power lines, and get instant, practical feedback right there on the spot.

- Safety Committee Meetings: For a larger factory, a dedicated safety committee with reps from different departments can go through the policy clause by clause. This makes sure you're getting perspectives from the warehouse crew, the machine operators, and everyone in between.

- Direct Surveys: Simple, anonymous surveys can be great for getting thoughts on specific risks or procedures, particularly on topics where people might be hesitant to speak up.

The trick is to ask open-ended questions. Instead of, "Do you agree with this rule?" try asking, "What could go wrong with this procedure on a really busy Friday afternoon?" You'll uncover practical gaps you never would have thought of.

When workers see their own feedback actually make it into the final policy, they take ownership. It becomes their policy, not just another rule handed down from on high.

Involving your team like this doesn't just make the policy stronger; it builds trust. It shows you respect their experience and are genuinely committed to making sure they go home safe.

Creating a Simple Communication Plan

Okay, so you've refined the policy with worker input. Now you have to launch it properly. A policy nobody knows about is worthless. Your communication plan doesn't need to be some glossy, 50-page document, but it does need to be thorough.

The goal is simple: make sure every single person, from new hires to subcontractors, understands their responsibilities. A good plan just needs to cover a few key areas.

Your Communication Checklist

- Official Launch: Announce the new policy at an all-hands meeting or a site-wide toolbox talk. Get a senior leader to explain why it's important and answer questions directly. This shows strong leadership backing.

- Induction Training: The policy needs to be a core part of your induction for all new starters. Don't just hand them a copy to read. Walk them through the key sections most relevant to their specific job.

- Regular Refreshers: Safety isn't "set and forget." Use regular meetings and toolbox talks to circle back to different parts of the policy. Maybe you focus on emergency procedures one month and hazard reporting the next.

- Make It Accessible: A policy locked in a filing cabinet is a dead policy. Pin it on noticeboards, save it on a shared company drive, and use a digital system like Safety Space to make it instantly available on any phone or tablet, anywhere on site.

By communicating the policy clearly and consistently, you keep it front-of-mind. This constant reinforcement is what helps embed safety procedures into your team’s daily habits, making the site safer for everyone.

Putting Your Policy Into Action With Training and Enforcement

You’ve done the hard work: your workplace safety and health policy is written, you’ve gathered feedback from the team, and it’s ready to go. But this is the critical moment where the document has to come to life. A policy sitting in a folder is useless; it needs to become part of your daily operations.

Without active training and consistent enforcement, even the best-written policy is just a piece of paper.

Making Training Practical and Relevant

Let's be honest, no one learns anything from a death-by-PowerPoint session in a stuffy meeting room. Effective training is the bridge between what the policy says and what your team actually does. It needs to be hands-on, practical, and directly address the real risks on your site.

Forget the generic safety videos. Your training has to connect directly to the clauses in your policy and the tasks your workers perform every day. If you’ve just installed a new piece of machinery, get the team around it for a physical walkthrough. Show them the safe operating procedure, don't just make them read the manual.

Think about the real-world situations your team faces.

- Task-Specific Drills: Don't just talk about the emergency plan, run a surprise fire drill. See how long it takes everyone to get out of the workshop and where the hold-ups are. That’s far more valuable than a theoretical discussion.

- Hands-On Equipment Use: Training needs to be interactive. When it comes to equipment, every little detail matters. For instance, showing your team how a specialized shop vacuum hose adapter connects properly to control dust isn’t just about the tool; it’s about reinforcing your policy on respiratory health and keeping everyone safe.

- Role-Playing Scenarios: Get your supervisors to role-play how they’d handle a situation where a worker refuses to follow a safety rule. This isn't about confrontation; it's about building their confidence to manage those tricky conversations constructively.

The goal here is to build competence and, more importantly, understanding. When a worker knows why a guard needs to be on a machine, they're much more likely to make sure it's always in place.

Fair and Consistent Enforcement

Now for the part that makes many managers uncomfortable: enforcement. A policy without consequences is just a friendly suggestion. Your policy document must lay out a clear, fair, and consistent disciplinary procedure so everyone knows what happens when safety rules are ignored.

This isn’t about creating a culture of fear. It’s about accountability and protecting the entire team. The procedure should be transparent and graduated.

A fair enforcement process focuses on corrective action, not just punishment. The first step might be a verbal warning and retraining, escalating only for repeated or serious breaches. The goal is to correct the action and reinforce the importance of the policy.

Your process should clearly outline the steps:

- Verbal Warning: For a minor, first-time slip-up, a documented conversation and a quick training refresher is usually all that’s needed.

- Written Warning: For repeated issues or more serious breaches, it’s time for a formal written warning.

- Final Warning or Other Action: Deliberately ignoring serious safety rules requires stronger action, as laid out in your company's HR policies.

Consistency is everything. If one supervisor is a stickler for PPE and another lets it slide, your policy loses all authority. The rules have to apply to everyone, from the apprentice to the CEO, every single time. If you're looking for ideas, you can explore different frameworks in a policies and procedure template to see how this section can be built out.

Using Digital Systems to Track and Monitor

Trying to manage all this with paper forms and spreadsheets is a recipe for disaster. It’s a massive administrative headache to keep track of who was trained on what, when their tickets expire, and document every enforcement action. This is where a digital system stops being a nice-to-have and becomes essential.

Manual vs Digital Policy Management

Let's break down the difference between the old way of doing things and using a modern platform. The gap is pretty significant.

| Feature | Paper & Spreadsheets | Safety Space Platform |

|---|---|---|

| Training Records | Manual data entry, stored in filing cabinets | Centralised, real-time records for every worker |

| Expiry Alerts | Requires manual calendar reminders (if you're lucky) | Automated notifications for refresher training and certifications |

| Enforcement Tracking | Inconsistent notes, hard to track patterns | Digital log of all warnings and actions, easily auditable |

| Reporting | Time-consuming to compile data, often out of date | Instant dashboards to spot trends and identify problem areas |

| Accessibility | Stuck in the office, inaccessible on site | Accessible anytime, anywhere from a phone or tablet |

The bottom line is that manual systems are slow, prone to error, and make it hard to see the bigger picture.

Using a platform like Safety Space lets you see all your training records in real time. You can tell at a glance who needs a refresher course or which teams might be struggling with compliance. This data helps you get ahead of problems before an incident happens.

A digital system removes the guesswork. It gives you a clear, auditable trail of all your training and enforcement activities, which is invaluable for proving due diligence and making smart decisions to constantly improve your safety program.

Keeping Your Policy Relevant with Regular Reviews

Your safety and health policy can't be a "set and forget" document. Let's be honest, sticking it in a drawer for five years is a surefire way to end up non-compliant, or worse, dealing with a serious incident. It needs to be a living, breathing guide that changes as your business, its risks, and the law evolve.

A practical review schedule is your best defence against an outdated policy. You should be doing a full review at least once every year, no exceptions. But some events just can't wait for the annual calendar reminder, they demand an immediate update.

Triggers for an Immediate Policy Review

Think of these as red flags. When they pop up, it’s time to pull out the policy and make sure it still holds up in the real world.

- After any serious incident or near-miss: An incident is a clear signal that a control failed. Your review needs to dig into why it failed and what you need to change in the policy to stop it from happening again.

- When new machinery or substances are introduced: New gear brings new risks. It's that simple. Your policy has to be updated to cover new operating procedures, training needs, and specific risk controls.

- Changes in key personnel: If a site supervisor or manager leaves, you can't just assume the new person knows their responsibilities. They need to be formally handed over, and the policy updated to reflect the new appointment.

- Following a risk assessment that finds new hazards: If a site audit turns up a previously unmanaged risk, the policy must be updated immediately to get that hazard under control.

- Updates to WHS legislation: Laws change. You've got to stay on top of these updates and tweak your policy to stay compliant. It's non-negotiable.

A quick tip: document every single review. Keep a simple log showing the date, who was involved, what changed, and when the new version was issued. This creates an essential audit trail that will save you a lot of headaches down the line.

While we often focus on physical injuries, the landscape is shifting. With mental health claims on the rise, WHS laws now demand that businesses actively manage psychosocial hazards like excessive workloads and workplace bullying. This means your reviews must start integrating psychological safety.

Communicating any changes is just as crucial as making them. You need to get the updated policy out to all staff, contractors, and anyone else who needs to see it, and you need to do it fast. This is where a digital platform really shines. A tool like Safety Space can handle this automatically, ensuring everyone is always working from the most current version and giving you a clear, simple record for any audits and compliance checks.

Still Got Questions About Safety Policies?

Even after laying everything out, a few questions always pop up when businesses are putting their safety policies into action. It’s completely normal. Here are some of the most common ones we hear from Australian businesses, with straight-to-the-point answers.

How Often Should We Be Reviewing This Thing?

The absolute minimum is once a year. But honestly, thinking of it as just an annual task is a mistake.

You need to pull that policy out and review it immediately if:

- A serious incident or a significant near-miss happens.

- You bring in new machinery, chemicals, or work processes.

- WHS laws change (and they do!).

- A fresh risk assessment uncovers something new you hadn't planned for.

Think of it as a living document, not a set-and-forget file.

Who's Actually on the Hook for This, Legally Speaking?

Under WHS law, the ultimate responsibility falls on the PCBU (Person Conducting a Business or Undertaking), that's the company itself.

But it doesn't stop there. Senior leaders and company officers have a personal duty to be proactive and ensure the business is meeting its safety obligations. That includes making sure an effective safety policy isn't just written, but is actually being used day-to-day.

What’s the Real Difference Between a Policy and a Procedure?

This one trips a lot of people up, but it's pretty simple when you break it down.

- A policy is your high-level commitment. It’s the ‘what’ and the ‘why’. It states your company’s stance on safety, outlines the big goals, and assigns broad responsibilities.

- A procedure is the boots-on-the-ground instruction manual. It's the 'how'. Think of a detailed, step-by-step guide for a specific task, like the lockout-tagout steps for machine maintenance or the exact form to fill out to report a hazard.

Your policy provides the framework, and your procedures are the detailed actions that bring that policy to life.

We’re Just a Small Business. Do We Really Need a Formal, Written Policy?

Yes. One hundred percent.

While a five-person workshop won't need the same beast of a document as a multi-site factory, having a written policy is a non-negotiable under Australian WHS law. It’s the foundation of your safety management. It proves your commitment and gives everyone, from the owner to the newest apprentice, a clear guide on how safety is handled. This is just as critical for a small team as it is for a massive corporation.

Tired of chasing paperwork and wrestling with spreadsheets to manage safety? Safety Space brings everything into one simple, real-time platform. It’s designed to give you clear oversight across all your sites without the headache. Book a free demo and see how we help you build a safer, more compliant workplace.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.