If you're in charge of safety on a construction site or in a factory, getting your head around the Work Health and Safety (WHS) Act and the WHS Regulation 2011 is non-negotiable. They're a team, but they play very different roles in your day-to-day.

Think of it this way: the WHS Act sets the destination, a safe workplace for everyone. But it's the WHS Regulation 2011 that gives you the turn-by-turn directions to actually get there.

The WHS Regulation and How It Works

The WHS Act lays down the big-picture legal duties. It establishes the primary duty of care for a 'person conducting a business or undertaking' (PCBU) to keep workers safe. But the Act won't tell you exactly how to manage the risk of a fall from a height or the specific way to handle a hazardous chemical.

That's where the WHS Regulation 2011 steps in. It provides the specific, prescriptive rules you have to follow to meet your obligations under the Act.

The Regulation is the playbook. It translates the broad principles of the Act into concrete, actionable requirements for specific hazards and work processes you see every day in high-risk environments.

This distinction is what really matters on the ground. The Act says you must provide a safe work environment. The Regulation tells you that for certain high-risk construction work, you must prepare a Safe Work Method Statement (SWMS). It’s the Regulation that gets into the nitty-gritty of machinery guarding, chemical exposure limits, and when you need to provide specific personal protective equipment (PPE).

WHS Act vs WHS Regulation 2011 At a Glance

To make it crystal clear, let’s break down the core differences. This table shows you how each piece of legislation functions and where you should be focusing your compliance efforts.

| Aspect | WHS Act | WHS Regulation 2011 |

|---|---|---|

| Purpose | Establishes the main principles and general duties of care. | Provides specific, mandatory rules to manage particular hazards. |

| Scope | Broad and goal-oriented, covering all workplaces. | Detailed and prescriptive, focusing on how to achieve safety. |

| Practical Example | Requires you to manage risks from airborne contaminants. | Specifies the exposure standards for certain chemicals and when you must conduct air monitoring. |

| Legal Status | Primary legislation (the main law). | Subordinate legislation (the detailed rules supporting the law). |

Grasping this two-part structure is the first step to building a solid safety system. Your daily tasks, from risk assessments to incident reports, are all guided by the detailed instructions found inside the WHS Regulation 2011.

To see how this fits into the bigger picture, check out our guide on the differences between OHS and WHS. This foundational knowledge helps put the Regulation into a clearer context.

Understanding Key Duties and Who Is Responsible

To get a handle on the WHS Regulation 2011, the first thing you need to nail down is who is actually responsible for safety. Forget traditional job titles for a moment. The law uses specific terms to pin down legal duties, making it clear who is accountable when things go wrong.

These duties don't exist in a vacuum. On any busy construction site or factory floor, you'll find responsibilities overlap. This forces different parties to communicate and work together to manage the exact same risks. The whole point is to create a strong web of responsibility where everyone knows exactly what part they play.

The three big terms you absolutely must understand are PCBU, officer, and worker. Getting these definitions right is the first practical step toward building a safety system that actually works and holds up under scrutiny.

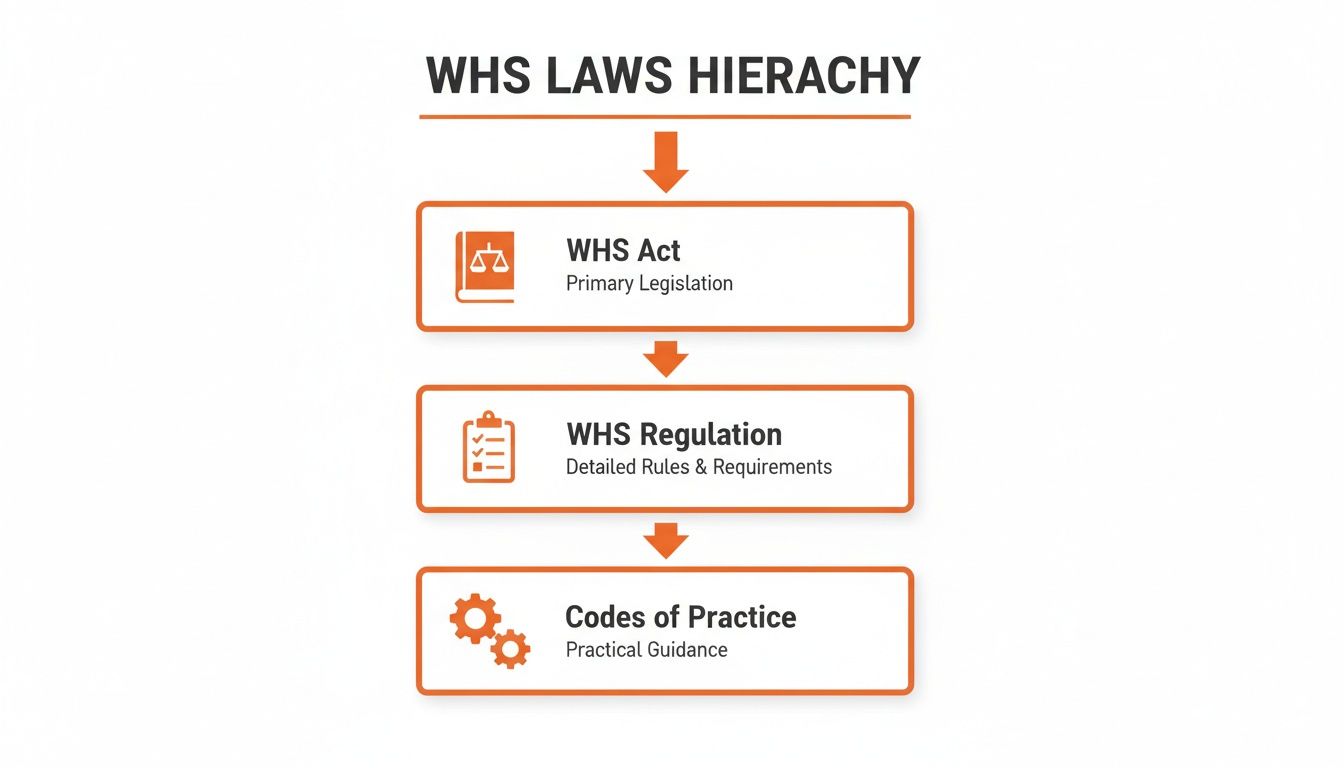

This diagram shows how the WHS Act, the WHS Regulation, and the Codes of Practice all fit together. Think of it as a hierarchy of rules.

As you can see, the Regulation is the practical rulebook. It takes the broad duties laid out in the Act and gives you the specific, hands-on instructions on how to meet them.

The Role of the PCBU

The term PCBU, which stands for Person Conducting a Business or Undertaking, is designed to be incredibly broad. It’s meant to cover every kind of modern work arrangement you can think of, from a massive construction firm to a lone sole trader working as a subcontractor.

A PCBU holds the primary duty of care. This is a heavy responsibility. It means they must do everything that is reasonably practicable to protect the health and safety of their workers and anyone else who might be affected by their work, like visitors or the general public.

Let's look at a typical building site:

- The principal contractor running the whole project is a PCBU. They have overall responsibility for the entire site.

- Every subcontracting company (the plumbers, the electricians, the scaffolders) is also a PCBU, responsible for their own team and the specific risks their work introduces.

- Even a sole trader hired for a specific job is considered a PCBU.

This layered structure means multiple PCBUs often share responsibility for the same hazard. If an electrician’s work creates a live wire risk, both the electrical subcontracting company and the principal contractor have a legal duty to make sure that risk is managed. You can't just pass the buck.

The Duties of an Officer

An officer isn't defined by their job title, but by their influence. They are the people who make, or help make, the big decisions that affect a substantial part of the business. We're talking about company directors, CEOs, and other senior leaders who have real control.

Their duty is distinct from a PCBU's. Officers have a personal duty to exercise due diligence. This means they have to be proactive in making sure the PCBU is actually meeting its safety obligations under the WHS Regulation 2011.

Due diligence is an active, ongoing process. It means an officer has to take real steps to stay informed about safety matters, understand the business's key hazards, and ensure there are enough resources, like time and money, to manage those risks properly. It’s not a 'set and forget' task.

A director of a manufacturing company, for example, must make sure there's a proper budget for upgrading machine guarding and that there’s a solid system in place for reporting incidents. If they fail to do this, they can be held personally liable.

What It Means to Be a Worker

Just like PCBU, the definition of a worker is extremely broad. It's not just about direct employees. It includes contractors, subcontractors, labour-hire staff, apprentices, work experience students, and even volunteers. If you're doing work in any capacity for a PCBU, you are legally considered a worker.

Workers have two fundamental duties:

- Take reasonable care of their own health and safety.

- Take reasonable care that what they do (or don't do) doesn't put others at risk.

This means following any reasonable safety instructions and cooperating with the PCBU’s policies and procedures. A crucial part of this is understanding safety documentation, like an MSDS for Natural Gas, which provides critical information for handling hazardous substances safely. This entire framework was built to tackle some sobering injury statistics. Before these harmonised laws, Australia recorded 128,735 serious workers' compensation claims in 2008–09 alone. While that was a 22% decrease from earlier years, it still meant 13.0 serious claims for every 1,000 employees, a number that was clearly far too high.

Applying Critical Rules in Construction and Manufacturing

Knowing who is responsible is the starting point. Now, let's get into the specific rules from the WHS Regulation 2011 that you’ll actually use day-to-day on a construction site or factory floor.

These aren't just theoretical lines in a textbook; they are the practical, hands-on instructions for managing your biggest risks.

High-risk industries like construction and manufacturing are where the WHS Regulation really shows its teeth. It provides the specific 'how-to' for managing everything from complex machinery and fall hazards to dangerous substances. The regulations were written to be applied, not just read.

We'll break down four critical areas that come up constantly: risk management, high-risk work, plant and structures, and hazardous chemicals. The goal is to show you what compliance actually looks like in the real world.

Mastering the Risk Management Process

At its heart, the WHS Regulation 2011 is all about a systematic approach to risk. This isn't a one-off task you tick off a list. It’s a continuous cycle: identify hazards, assess the potential for harm, control the risk, and then review those controls to make sure they’re still working.

For example, imagine your workshop is installing a new hydraulic press. A simple 'tick-and-flick' safety check just won’t cut it. The regulation demands a far more thorough approach.

Practical Risk Assessment Steps:

- Identify Hazards: What could actually hurt someone? Think about moving parts (crushing), high-pressure hydraulic lines (injection injuries), electrical systems (shock), and noise (hearing loss).

- Assess Risks: How likely is it to happen, and how bad would it be? An unguarded press has a very high chance of causing a catastrophic injury.

- Implement Controls: You must follow the hierarchy of controls, starting with the most effective options first. This means engineering controls like fixed guarding and light curtains are your first move, long before you even think about administrative controls like warning signs or PPE.

- Review Controls: After the press is installed, you have to circle back. Are the guards effective? Have they created a new, unforeseen hazard? This review process has to be ongoing.

The regulations are designed to push you away from the lazy habit of just handing out PPE. For new machinery, the clear expectation is that risks are engineered out of the process from the start. PPE is, and always will be, the last line of defence.

This systematic approach is mandatory for every single hazard you identify in the workplace. It's the foundation of your entire safety system.

Handling High-Risk Construction Work

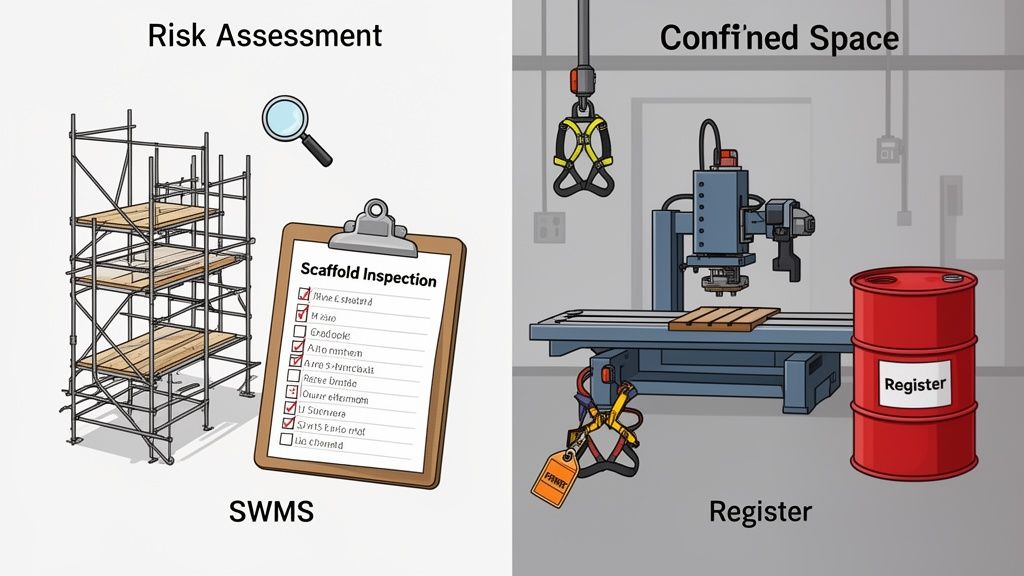

For certain high-stakes activities, the WHS Regulation demands more than just a standard risk assessment. It mandates a Safe Work Method Statement (SWMS) for any of the 19 specified high-risk construction work activities.

A SWMS isn't just more paperwork. It's a living document that should be developed with the people who are actually doing the job. It breaks down the task step-by-step, identifies the specific hazards at each stage, and spells out the exact control measures that will be used.

Let's take working on scaffolding where there's a risk of falling more than two metres. A compliant SWMS must clearly outline:

- The specific tasks being performed on the scaffold.

- The hazards involved (e.g., fall from height, dropped objects, scaffold collapse).

- The controls for each hazard (e.g., ensuring guardrails are in place, using tool lanyards, confirming the scaffold has been inspected and tagged safe).

- Who is responsible for making sure the controls are in place.

The SWMS has to be kept on-site and be easily accessible to the crew doing the work. If the job changes, the SWMS must be reviewed and updated on the spot. No exceptions.

Managing Plant and Structures Safely

The term 'plant' covers everything from a handheld angle grinder to a tower crane. 'Structures' includes things like scaffolding, tunnels, and excavation sites. The WHS Regulation 2011 has incredibly detailed rules for the inspection, maintenance, and safe operation of all this gear.

Take scaffolding on a multi-storey building site. The regulations put strict, non-negotiable duties on the PCBU.

Key Scaffolding Requirements:

- Competent Installation: The scaffold must be put up, altered, and taken down by someone holding the appropriate high-risk work licence.

- Regular Inspections: A competent person must inspect the scaffold before it's first used, after any event that could affect its stability (like a bad storm), and at least every 30 days.

- Handover Certificates: For certain types of scaffolds, a formal handover certificate must be given to the principal contractor to confirm it's been inspected and is safe for use.

- Signage: You must prevent unauthorised access, especially during erection or dismantling, with clear signage (e.g., 'Scaffold Incomplete - Do Not Use').

These rules are so prescriptive for a reason. The data doesn't lie: falls from height are a leading cause of fatalities and serious injuries in construction. The regulations are there to force a structured, documented approach to managing these temporary structures and save lives.

Controlling Hazardous Chemicals

Finally, Part 7.1 of the WHS Regulation 2011 lays out the specific rules for managing risks from hazardous chemicals, which are everywhere in manufacturing and construction.

Compliance here involves several key actions. Let's say your factory uses a variety of industrial solvents and cleaning agents. You are required to:

- Obtain Safety Data Sheets (SDS): You must have a current SDS from the supplier for every single hazardous chemical you use.

- Maintain a Register: You need to keep a register of all hazardous chemicals on site, with the SDS for each readily accessible to all workers. No excuses.

- Ensure Correct Labelling: All containers must be properly labelled in English, with the product name, hazard pictograms, and warnings clearly visible.

- Manage Risks: You must control exposure through proper ventilation, safe storage, and by providing the correct PPE as identified in the SDS.

This isn't just about having the right documents filed away. It's about using that information to keep people safe on the job, every single day.

A Practical Plan for WHS Regulation 2011 Compliance

Knowing the rules is one thing, but putting them into action on a busy worksite is another beast entirely. To meet your obligations under the WHS Regulation 2011 without drowning in paperwork, you need a solid, practical plan. The goal here isn't to create a mountain of documents that just sit in a file cabinet; it's about building a straightforward system that actually works on the ground.

This is about setting up a logical, repeatable process that covers your key duties, from figuring out who's in charge to managing risks day-to-day. A good compliance plan is your roadmap.

Let's walk through a five-step process you can use as a checklist. Whether you're building a system from scratch or just sense-checking the one you've got, this is an actionable framework designed for managers in the thick of it.

Step 1 Identify All PCBUs and Officers

First things first: you need a clear map of responsibility. The WHS Regulation 2011 is built on the duties of PCBUs and their officers, so you absolutely must know who fits these roles in your operation and on every project.

Think about a typical construction site. You’d need to identify:

- The principal contractor as the primary PCBU.

- Every subcontracting company (plumbers, electricians, scaffolders) as their own individual PCBU.

- Any labour-hire agencies supplying workers to the site, who are also considered PCBUs.

- Company directors and senior leaders who make the big operational decisions; they are the officers.

This list is your foundation. Without it, you can't manage overlapping duties or make sure the people with due diligence responsibilities are actually doing their part.

Step 2 Review Your System Against Key Rules

Once you know who is responsible, you need to check if your current safety management system is actually up to the specific demands of the WHS Regulation 2011. This isn't just a quick tick-and-flick exercise. It’s a gap analysis to find exactly where your procedures fall short.

Zero in on the high-risk activities in your industry. For a manufacturing plant, that means scrutinising your machine guarding, lockout/tagout procedures, and how you handle chemicals. For a construction company, it’s all about your systems for scaffold inspections, live electrical work, and preventing falls from height.

A common mistake is having a generic safety manual that doesn't actually address the specific, prescriptive requirements of the regulations. Your review must confirm you have clear, documented procedures for things like confined space entry permits or preparing a Safe Work Method Statement (SWMS) for high-risk construction work.

This step turns vague compliance goals into a concrete to-do list, showing you exactly what needs to be fixed or created.

Step 3 Put a Risk Management Process in Place

Having a documented risk management process is non-negotiable under the WHS Regulation 2011. This can't be an afterthought; it needs to be applied to every single task, from routine maintenance to complex installations. It has to be a system your workers understand and use every day.

A practical risk management process includes:

- A method for identifying hazards: How do you spot trouble before it happens? Think pre-start checks, site walks, and genuinely listening to worker feedback.

- Tools for assessing risk: You need a consistent way to judge how likely a hazard is to cause harm and how bad it could be. Simple risk matrices work well. For more help, you might be interested in our guide on using a WHS risk assessment template correctly.

- Applying the hierarchy of controls: Your process must force people to consider higher-level controls (like elimination or engineering) before just handing out more PPE.

- A system for review: Controls aren't set-and-forget. They must be reviewed regularly and after any incident to make sure they're still working.

Let's be honest, clunky spreadsheets or paper forms make this a headache. Modern digital tools can make this process far more manageable, ensuring everyone uses the same templates and records are easy to find.

Step 4 Set Up Clear Consultation Procedures

Consultation isn't a "nice-to-have", it’s a core duty. You must consult with workers on WHS matters that affect them, and your compliance plan needs to spell out exactly how and when this will happen.

Effective consultation is a two-way street, not a top-down memo. It’s a genuine exchange of information.

Practical Consultation Methods:

- Scheduled toolbox talks: Perfect for discussing specific daily hazards and getting immediate feedback from the crew on the ground.

- Health and Safety Representatives (HSRs): Make sure your HSRs are properly elected and trained. They provide a formal channel for workers to raise concerns.

- WHS committee meetings: For larger organisations, these committees are a great structured forum for managers and worker reps to tackle safety performance and ongoing issues.

Your procedures should also specify how you record feedback and what actions you'll take. This shows you're taking it seriously and actually closing the loop.

Step 5 Create a Reliable Record-Keeping System

Finally, you need a bulletproof system for keeping records. If an incident happens or a regulator shows up, you have to be able to prove you've been doing the right thing. Your memory doesn't count.

Key records you absolutely must maintain include:

- Incident reports and investigation findings.

- Risk assessments and SWMS for any high-risk work.

- Training records for everyone, covering inductions and specific competencies.

- Inspection and maintenance logs for all plant and equipment.

- Minutes from WHS committee meetings or other formal consultations.

Relying on a stack of papers in a dusty site office is just asking for trouble. A digital management system gives you a single source of truth, making your records secure, searchable, and ready for an audit or investigation at a moment's notice.

Penalties and Enforcement for Non-Compliance

Let's be clear: failing to follow the WHS Regulation 2011 isn't just a paperwork problem. It carries serious, real-world consequences. When a regulator steps onto your worksite, they have significant power to enforce the law, and understanding what they can do is critical for any business owner or manager.

The fallout can range from on-the-spot notices that shut down work immediately to crippling financial penalties and even jail time for the worst breaches. These aren't empty threats; regulators use them every day to hold businesses and their leaders accountable for failing to keep people safe.

Regulator Actions and Notices

When a WHS inspector finds a breach, they won't just leave a friendly note. They issue legally binding notices that demand immediate action and come with heavy penalties if you ignore them. The two you’re most likely to see are Improvement Notices and Prohibition Notices.

An Improvement Notice is your formal warning to fix a specific problem. It will clearly state what's wrong and give you a deadline to sort it out. For instance, an inspector might find you don't have a compliant register for hazardous chemicals and issue a notice giving you 14 days to create one.

A Prohibition Notice, on the other hand, is much more serious. This is the inspector's emergency stop button. They use it when they believe an activity poses an immediate and serious risk to someone's health. The notice orders you to stop that activity right now, and you can't restart until the inspector is satisfied the risk is gone.

Think of it this way: a Prohibition Notice can shut down a production line, halt work on a specific part of a construction site, or take a dangerous piece of machinery out of service on the spot. It’s a direct intervention designed to prevent a potential fatality or serious injury from happening.

Ignoring either of these notices is a serious offence in its own right, leading to more fines on top of the original breach.

Understanding Offence Categories and Penalties

If a breach is serious enough to end up in court, the penalties are structured into three main categories. These tiers are based on how severe the failure was and the level of harm or risk it created. The financial penalties are substantial and can hit both the company (the PCBU) and individuals personally.

Here’s a breakdown of the three categories under the model WHS laws:

- Category 1: This is the most serious offence imaginable. It applies when a PCBU, who has a safety duty, recklessly exposes someone to a risk of death or serious injury. This is where you see the biggest fines and potential prison sentences for individuals.

- Category 2: This is for when a PCBU fails in their safety duty and exposes someone to a risk of death or serious injury. The key difference from Category 1 is that the element of "recklessness" isn't required for a conviction.

- Category 3: This is the least severe category and covers any other failure to comply with a health and safety duty.

The potential fines are staggering. For a Category 1 offence, a corporation can face penalties of over $3 million. An officer of the company can be fined more than $600,000 and face up to five years in prison. These numbers make it clear: the WHS Regulation 2011 holds both companies and their leaders personally responsible.

The Real Cost of Getting It Wrong

The impact of a breach goes way beyond the initial fines. A major incident or prosecution can cause massive operational disruption, destroy your company's reputation, and make it nearly impossible to win future contracts.

The personal liability for officers is a game-changer, too. A director can't just claim ignorance about a safety failure; the law demands they be proactive and exercise due diligence.

For example, a construction company was recently prosecuted after a worker was badly injured in a fall. The investigation found that the control measures detailed in their own Safe Work Method Statement were never actually put in place. The company copped a six-figure fine, but it didn't stop there. The director was also prosecuted personally for failing in their duties. This case is a perfect, real-world example of how the WHS Regulation 2011 connects corporate failures directly to the people in charge.

How the Regulation Varies by State and Territory

The whole point of harmonised safety laws was to create a single, national system. A great idea in theory, but the reality on the ground is a bit more complicated.

The WHS Regulation 2011 is the model everyone works from, but how it’s adopted, and the specific version in play, changes depending on which side of the state border your worksite is on. Getting this wrong isn't a minor slip-up; it can leave huge gaps in your compliance.

First things first: not every state got on board. Victoria has always marched to the beat of its own drum, sticking with its own well-established Occupational Health and Safety (OHS) laws. This is a big one to remember. Your compliance checklist for a job in Melbourne will look quite different from one for a site in Sydney or Brisbane.

Western Australia was the other major holdout for years, but they finally came into the fold, rolling out their version of the model WHS laws in 2022. This was a massive shift for businesses in WA, bringing them much more in line with the rest of the country.

State and Territory Adoption Status

For any business operating across state lines, knowing these local differences is non-negotiable. It’s the only way to ensure you're covered everywhere you work.

Here’s a quick-reference guide to see who’s using the model WHS laws and who isn't, with handy links to the local safety regulators.

WHS Regulation 2011 Adoption Across Australia

| State/Territory | Adoption Status | Link to Local Regulator |

|---|---|---|

| New South Wales | Adopted | SafeWork NSW |

| Queensland | Adopted | WorkSafe QLD |

| South Australia | Adopted | SafeWork SA |

| Tasmania | Adopted | WorkSafe Tasmania |

| Western Australia | Adopted (in 2022) | WorkSafe WA |

| Victoria | Not Adopted | WorkSafe Victoria |

| ACT | Adopted | WorkSafe ACT |

| Northern Territory | Adopted | NT WorkSafe |

Even in the states that have adopted the model laws, don't assume they are identical.

Always check in with the local regulator. While the core principles are the same, small variations in the regulations or local codes of practice can have a surprisingly big impact on your day-to-day compliance duties.

Getting a feel for how a specific jurisdiction applies these rules is key. For a practical example, you can take a closer look at Queensland's WHS legislation to see how the framework translates into real-world obligations. This kind of state-level knowledge is exactly what you need to keep your operations compliant and your team safe.

Common Questions About the WHS Regulation 2011

Even with a solid plan, practical questions about the WHS Regulation 2011 always pop up on the job. We get it. Let's run through some of the most common points of confusion we see managers run into in construction and manufacturing, and give you some clear, direct answers.

Does My Business Have to Pay for PPE?

Yes, absolutely. Under the WHS Regulation, the PCBU has a cast-iron duty to provide any necessary Personal Protective Equipment (PPE) to workers, completely free of charge. You can't ask a worker to chip in for their own gear or make buying it a condition of their employment.

And it doesn't stop there. Your responsibility also covers making sure the PPE is right for the job, fits the worker properly, and is kept in good nick.

What Is the Difference Between a Hazard and a Risk?

This is a classic mix-up, but getting it right is critical for compliance. Think of it this way:

- A hazard is anything with the potential to cause harm. An unguarded saw, a slippery floor, or a drum of chemicals are all hazards. They're just sitting there, waiting for something to happen.

- A risk is the likelihood of that hazard actually hurting someone, combined with how bad the injury could be.

The WHS Regulation 2011 is all about managing risks. To do that, you first have to spot the hazards, then figure out the chances of an incident and what the consequences would look like.

Do I Still Need a SWMS if I've Done a Risk Assessment?

Yes, for certain high-stakes jobs, you absolutely do. A risk assessment is a foundational requirement for all work, but a Safe Work Method Statement (SWMS) is a specific, more detailed document required for any of the 19 high-risk construction work activities.

They serve different purposes and one doesn't replace the other.

A risk assessment identifies and controls hazards for a general task. A SWMS is a detailed, step-by-step game plan for a specific high-risk job, and you have to develop it in consultation with the people actually doing the work. They aren't interchangeable.

Trying to manage every detail of the WHS Regulation 2011 with paper and spreadsheets is a tough gig. Safety Space was built to replace that outdated approach with a single, easy-to-use platform. It helps you nail your risk assessments, SWMS, and subcontractor compliance, all in one spot. See how you can make your safety management simple and effective by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.